Automotive

Hyundai has been inching toward a future where robots do way over shuttle parts around a factory floor, and its latest CES 2026 showing made that crystal clear. After buying Boston Dynamics in 2021, the apparent play gave the look of using Spot robot dogs for inspections and safety walk-throughs. As a substitute, Hyundai is aiming higher with Atlas, a humanoid robot it wants working alongside people on the assembly line, eventually taking up the sorts of jobs that grind you down: repetitive motions, awkward lifts, and tasks that get sketchy in a rush.

The massive headline is scale. Hyundai says it wants a production system able to constructing 30,000 robots a 12 months starting in 2028, and it plans to place Atlas to work that very same 12 months at Hyundai Motor Group Metaplant America in Georgia. That matters because this will not be some far-off “someday” concept tied to a single pilot line. Hyundai is talking a couple of repeatable factory model and an actual deployment timeline, starting with smaller jobs before moving into more meaningful assembly work by 2030.

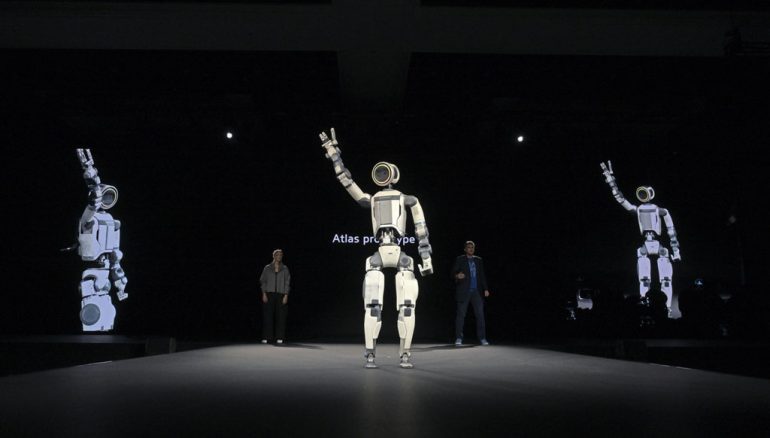

In the event you watched the stage show, you most likely noticed the split between spectacle and reality. Atlas was on the market moving with a sort of uncanny athleticism, posing and flexing in ways in which no human body can. Hyundai and Boston Dynamics also acknowledged that the show robot was teleoperated backstage, which is essentially the robotics version of claiming, “This can be a demo, not the finished product.” The more interesting detail was the production-intent Atlas shown in blue, which is the sort of machine Hyundai hopes can clock in for factory duty within the near term.

After all, the moment you say “humanoid robots in automobile factories,” everyone asks the identical query: what happens to jobs? Hyundai’s leadership isn’t pretending that nothing changes. The corporate’s vice chairman, Jaehoon Chang, framed the plan as “human-centered” robotics, arguing that recent roles shall be needed to guide, supervise, and maintain these machines, plus construct out a broader robotics ecosystem. That sounds reassuring, nevertheless it also hints at the true shift: fewer people doing rote line work, more people doing oversight, upkeep, and higher-skill tasks if Hyundai can actually pull this off at scale.

Then there’s the cash side, and here’s where Hyundai is attempting to keep expectations grounded. In the event you were hoping robots would immediately unlock bargain-priced recent cars, Hyundai’s manufacturing leadership says to not count on it. The corporate estimates labor is roughly 5% to 10% of auto manufacturing costs, so even meaningful automation doesn’t routinely translate into dramatic sticker-price drops. Hyundai’s pitch is more about consistent construct quality and safer working conditions, with the fee savings showing up quietly in efficiency as an alternative of headline-grabbing price cuts.

What makes this greater than a one-off automaker flex is what Hyundai and Boston Dynamics need to do beyond the factory gates. Boston Dynamics CEO Robert Playter has talked about offering Atlas through a robotics-as-a-service subscription model, and the corporate remains to be selling Spot robot dogs with a revenue goal around $100 million this 12 months. Hyundai also has partnerships in the combo to speed up the “physical AI” side of robotics, including work tied to Google DeepMind and Nvidia. Put all of it together and you may see the larger Hyundai bet: Atlas will not be only a factory helper, it’s the opening move toward humanoid robots that would eventually show up in logistics, healthcare, and elder care, with Hyundai using car-building scale to mass-produce the employees of the longer term.

FOLLOW US TODAY:

Lloyd Tobias is a seasoned automotive journalist and passionate enthusiast with over 15 years of experience immersed on this planet of cars. Whether it’s exploring the newest advancements in automotive technology or keeping a detailed pulse on breaking industry news, Lloyd brings a pointy perspective and a deep appreciation for all things automotive. His writing blends technical insight with real-world enthusiasm, making his contributions each informative and fascinating for readers who share his love for the drive. When he’s not behind the keyboard or under the hood, Lloyd enjoys test driving the most recent models and staying ahead of the curve in an ever-evolving automotive landscape.

This Article First Appeared At www.automotiveaddicts.com