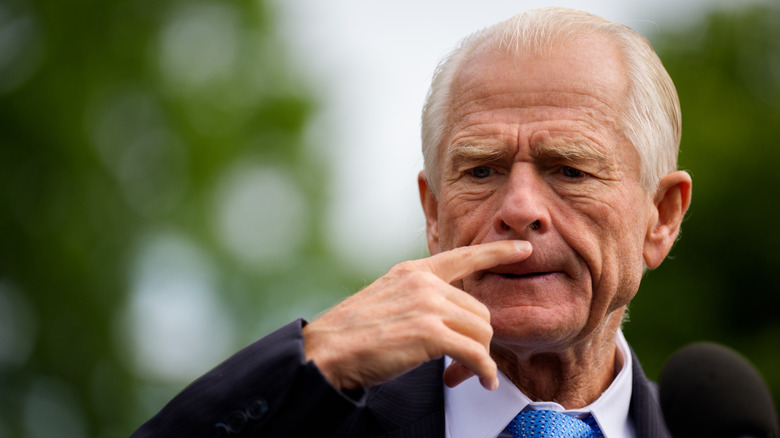

The Trump administration’s shambolic tariff policy is imagined to send a transparent signal to domestic and foreign automakers alike: Make more vehicles in the nice old US of A! Trump trade advisor Peter Navarro has been beating this drum for months with wild-eyed conviction, as has Commerce Secretary Howard Lutnick, offering the inevitability of a U.S. auto manufacturing restoration as a type of fait accompli.

We currently import about eight million vehicles a 12 months, making up half of the 16 million annual US sales marketplace for cars and light-weight trucks. Tariffs, broadly speaking, can even have an effect on the availability chain; it has been noted that many, many automobile components cross the US-Canada and US-Mexico borders quite a few times before ending up in finished vehicles.

So, what would occur if the administration’s nirvana of a 100% made-in-USA vehicle got here to pass? Is it even possible? CNBC’s Mike Wayland reported out the query and concluded that, well … it’s complicated. Mike is essentially correct – however the complications mainly concern the staggering expense of all-American production. The reality is that, whenever you drill down into the main points, it’s effectively not possible to construct a automobile entirely inside U.S. borders.

It is the little things that count

I’ll explain by providing a teensy-weensy example: I have been lucky to have toured quite a few assembly lines. Contained in the plants, you may see some great big robots and a lot of high-tech computer screens and whole engines being lowered into unfinished chassis. But you may also see quite a few bins full of screws and bolts and clips and all manner of fiddly little components that, you already know, hold the automobile together. These bits will not be American made because it will be unbelievably costly to pay for American-made bits.

Now let’s zoom out. Each automobile manufactured anywhere on Earth has something called a “bill of materials,” or BOM, that ultimately dictates its existence. Yes, there are some vehicles – exotic hypercars and so forth – that do not live and die by the BOM, but for each other automobile or truck, from low-cost subcompacts to luxury 4 doors, the BOM is destiny. The automakers devote massive amounts of planning time, energy, and resources to creating the BOM work for a automobile they need to sell. The engineering costs alone are huge (automotive engineers are well paid, as they needs to be, for his or her expertise).

The BOM can’t be avoided. In his story, with the help of some analysts, Wayland works through how a carmaker could get as close as possible to 100% US content, going to date as to invent a brand new company that is all U.S.A. and has to sell its vehicle for upwards of … $400,000! Fun stuff, but in point of fact, the discussion would never even start, because everybody would already know, from square one, that the BOM would not fly.

What the Trumpers do not know

Other than Elon Musk, who doesn’t appear to be offering his extensive grasp of this topic to any of Trump’s advisors, no person within the administration knows anything about twenty first century manufacturing. Nonetheless, they’ve “designed” and rolled out probably the most ambitious disruption to the worldwide manufacturing economy in human history.

The tip goal is solely unachievable. GM and Ford have already clearly flashed a warning on that front, predicting a combined $6.5-billion hit to their profits for 2025. Ford’s annual net profit might be knocked down by 25% ; the $4-5 billion that GM expects to not make in 2025 is half of what the General has racked up in a typical 12 months for the reason that firm emerged from bankruptcy over a decade ago.

For example that, by some means, the boards of those firms resolve to go together with Trump and spend the billions that will be required to construct the factories and yank back production from outside the U.S. borders. They might then be operationally doomed because they would not have the option to sell for enough money, with acceptable margins, the cars and trucks that will eventually be built. The embedded economics of the auto industry are merciless. When you don’t make cash, you borrow money to cover the gap. But in case you don’t start making a living in some unspecified time in the future, the debt kills you. Fast.

That’s, literally, the underside line. The carmakers cannot afford Trump’s tariffs, and they cannot afford to make the changes that the tariffs demand. The alarming thing is that no person within the administration seems to have figured this out.

This Article First Appeared At www.jalopnik.com